Four Core Technologies

There are many steps involved in the production and medical use of exosomes (EVs). We have developed unique core technologies at each step to establish a high-quality, scalable EV production platform.

①"Prime-EV®": Cell Activation Technology for the Stable Production of Highly Efficacious Natural-Type EVs

When culturing cells, activating (priming) them with specific stimuli can enhance the therapeutic components (such as proteins and nucleic acids) of the extracellular vesicles (EVs) they produce. However, determining the optimal stimulation conditions to enhance these components for a specific therapeutic purpose is not straightforward. To address this, we have developed a cell activation technology that enables the stable manufacturing of EVs with high therapeutic effects. This was achieved by using our proprietary analytical technology (see ④ below) to identify the optimal stimulation conditions while verifying EV potency and the content of efficacy markers. This allows us to supply EV formulations with guaranteed efficacy, even during scale-up and commercial production. We call these natural-type EVs, produced with our cell activation technology, "Prime-EV®". (Patent pending*1)

② "Smart-EV™": Technology for Creating Engineered EVs for a Next-Generation Drug Delivery System (DDS)

Applying genetic modifications to EV-producing cells makes it possible to load various molecules, such as antigens and nucleic acids, onto the EVs. Such engineered EVs show great promise for application as a drug delivery system (DDS) in vaccines and nucleic acid therapies. We are conducting joint research with Associate Professor Ryosuke Kojima of the University of Tokyo's Graduate School of Medicine, a leading expert in EV engineering, and Professor Ken Ishii of the University of Tokyo's Institute of Medical Science, a world-class researcher in vaccine science. Through this collaboration, we are advancing exploratory research on "Smart-EV™," an engineered EV designed to enhance the therapeutic effects against specific diseases by loading multiple molecules.

We exclusively utilize the "plug-and-play" technology*2 that Prof. Ishii and his team invented to load antigens onto EVs. To load nucleic acids (mRNA) and deliver them into target cells, we use the EXOtic device technology*3 from Assoc. Prof. Kojima's lab. Our initial focus is on a Smart-EV™ endowed with the ability to freely control the immune system by designing its loaded antigens and nucleic acids. As a primary application, we envision the development of EV vaccines loaded with immunoregulatory components.

Furthermore, we consider adding an active targeting function to Smart-EV™ to enhance delivery efficiency to specific organs and cells. Viral vectors and lipid nanoparticles (LNPs) are used to deliver vaccines and nucleic acid drugs, but they face challenges related to safety, efficacy, and biodistribution. Smart-EV™ with active targeting capabilities has the potential to solve these issues and is expected to be developed as a next-generation DDS that is widely applicable to cancer therapy, nucleic acid medicine, and gene therapy.

③ "INPACT-EV®": High-Yield EV Purification Technology that Preserves Activity

Cell culture supernatant contains various components besides EVs, some of which can be harmful or inhibit the therapeutic effects of EVs. Therefore, it is crucial to purify EVs to a high degree of purity, while taking care not to compromise their activity in the process. We have established INPACT-EV®, a purification technology optimized for EV production. This was achieved by evaluating numerous ultrafiltration membranes and separation columns commonly used in biopharmaceutical manufacturing and adjusting their operating parameters. The INPACT-EV® system is automatically controlled by software and can purify large quantities of EVs with high recovery efficiency, without causing physical or chemical damage.

④ "EV-QUEST™": EV Analysis Technology to Ensure Reproducibility of Efficacy

We have independently developed an analytical technology to quantitatively evaluate whether purified EVs exhibit the therapeutic effect required for their intended use. At its core are cell-based assays that measure potency according to the EV's mechanism of action, and a series of analytical methods to identify and quantify marker molecules associated with therapeutic efficacy. These analytical technologies allow us to enhance the reproducibility of efficacy at the non-clinical and clinical trial stages. The development of technologies ①, ②, and ③ is supported by this foundational analytical technology.

- *1: WO2024/242132 “EXTRACELLULAR VESICLES OBTAINED FROM CELLS STIMULATED UNDER SPECIFIC CONDITIONS, AND PHARMACEUTICAL COMPOSITION CONTAINING SAID EXTRACELLULAR VESICLES”

- *2: Patent No. JP6786074, US12209115B2, US12319727B2: "Exosome-targeted DNA vaccine"

- *3: Nat Commun. 2018 Apr 3;9(1):1305.

Research Environment

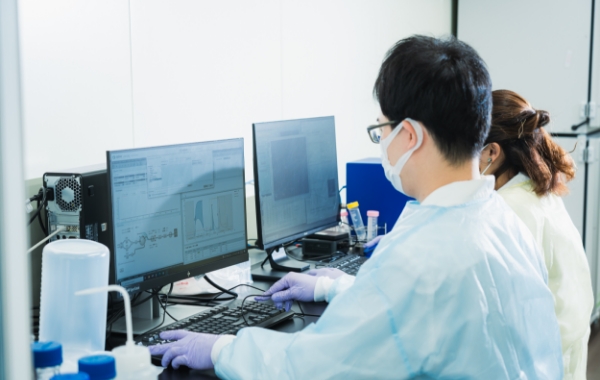

In-house Lab

Our company is located in the Inspired. Lab, an innovation space in the heart of Tokyo. This unique environment allows us to interact with other companies and academia, fostering opportunities for groundbreaking innovations.

Our state-of-the-art wet lab is equipped to conduct cell culture, BSL2 experiments, exosome purification, and analysis. Our prime location, directly connected to the Otemachi subway station, enables us to efficiently utilize nearby medical universities' facilities and equipment, enhancing our productivity and cost-effectiveness.

In January 2024, we launched a cleanroom for exosome production. We are currently collaborating with an experienced biopharmaceutical contract manufacturing organization (CDMO) to establish cGMP for Phase1/2 clinical trials.

Research Team

Our team comprises experienced researchers from pharmaceutical companies, working together to achieve common goals. We collaborate with top academic researchers in basic and clinical fields to enhance our research productivity and provide skill development opportunities for our in-house researchers.

Compliance

We are committed to conducting research and development that adheres to the highest scientific and ethical standards. Our Research Ethics Review Committee and Recombinant DNA Experiment Safety Committee ensure compliance with laws, guidelines, and internal regulations.

We have established "Research Ethics Regulations" and mandatory training to guide our employees in conducting research activities with integrity. Our management team fosters a corporate culture that encourages open, evidence-based discussions and ensures the psychological safety of our employees.